The Former Jet

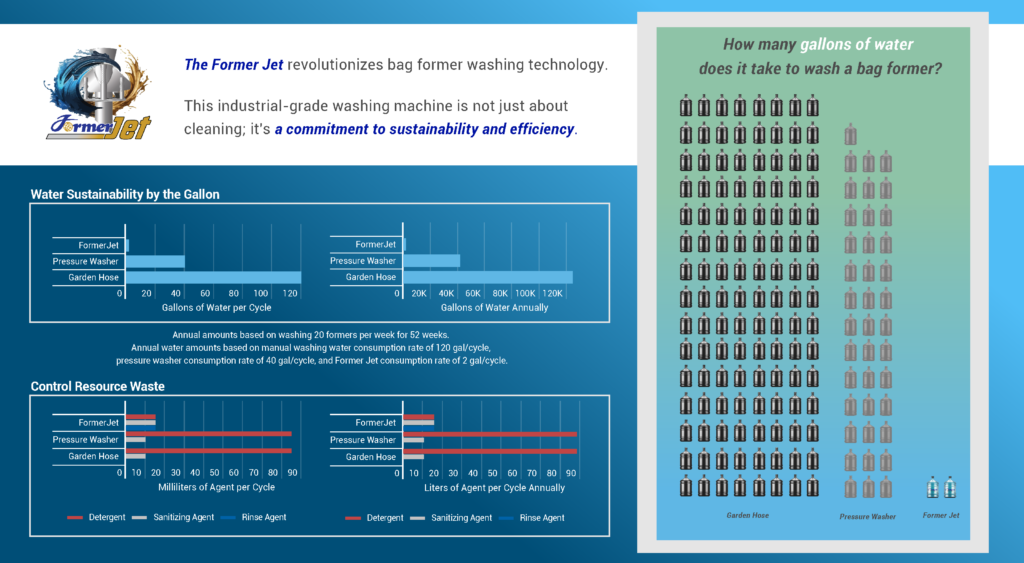

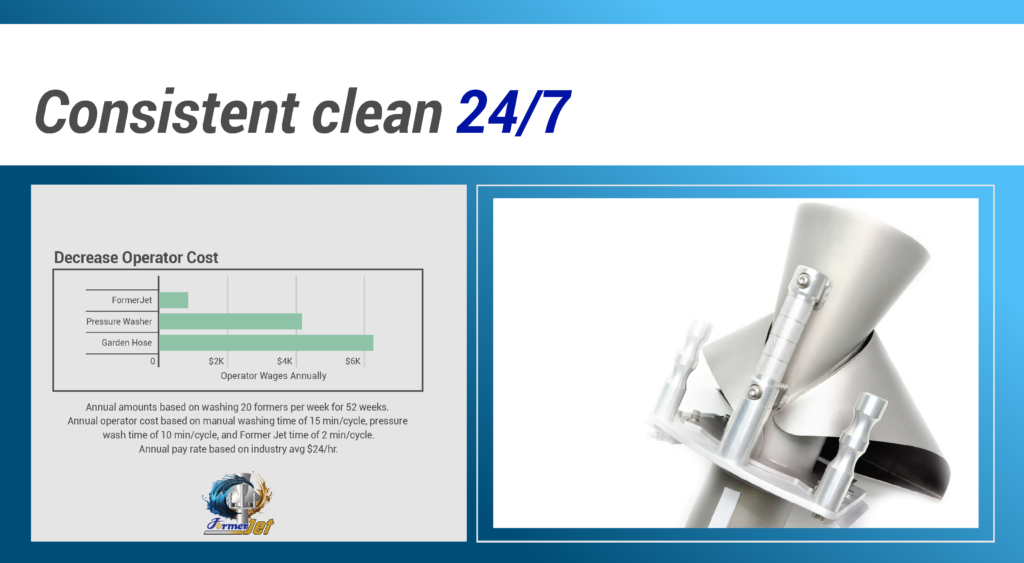

Imagine washing a former using only 2 gallons of water, and completing the task in 2 minutes.

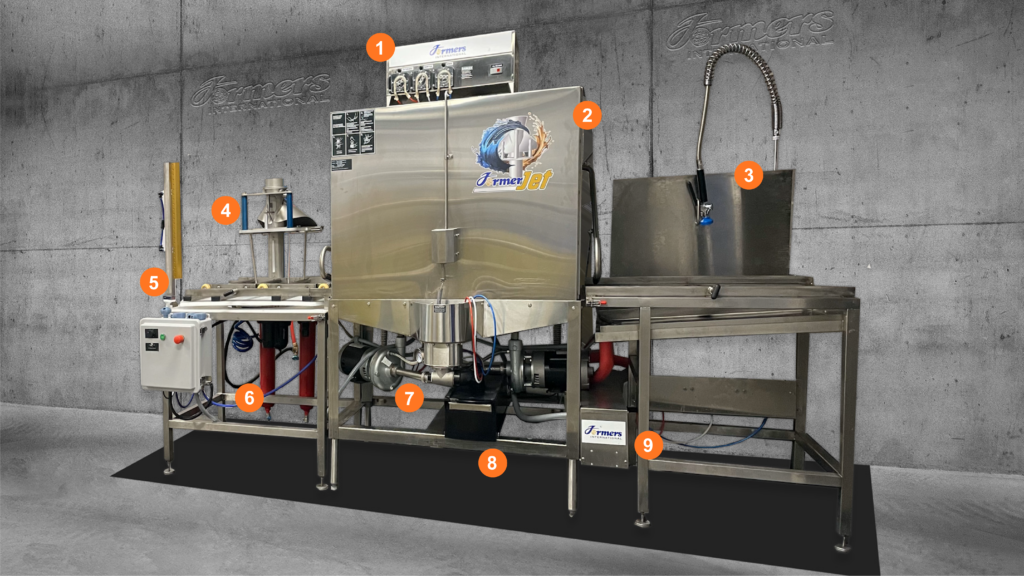

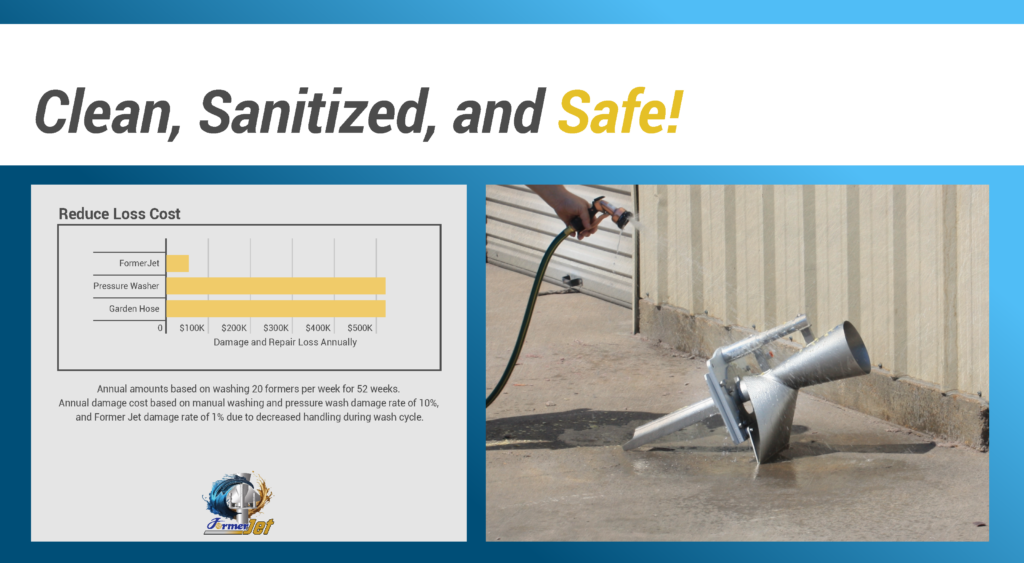

Fully Customizable to meet the needs of each facility, the Former Jet saves time, water, and reduces cost of loss due to mishandling during a manual wash.

Formers International proudly introduces the Former Jet, a groundbreaking revolution in bag former washing technology. This industrial-grade machine is more than just a cleaning solution; it’s a commitment to sustainability and efficiency, tailored for the needs of global food processing and packaging industry.